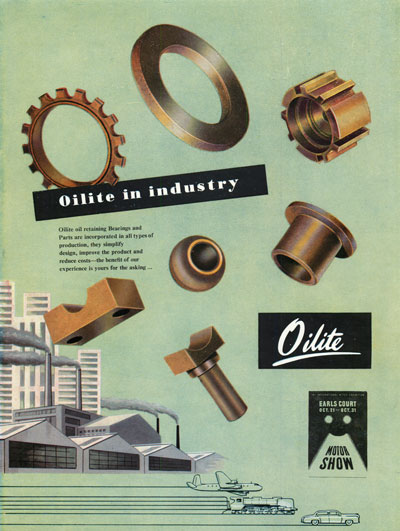

After almost 90 years Oilite bearings are still the undisputed market leader in sintered self-lubricating bearings. The technical knowledge and manufacturing expertise behind Oilite bearings have resulted in a vast array of sophisticated, high-quality components that are supplied across a wide range of industries throughout the world. Oilite bearings have a rich history dating back to the 1930s when they were developed by Chrysler. They have since been used in everything from the iconic Supermarine Spitfire to Formula 1 cars. Oilite bearings continue to set the standard for all other self-lubricating bearings and Bowman International is proud to be the sole supplier of genuine Oilite bearings in the UK and Europe in partnership with Beemer Precision Inc. in the USA.

Oilite® is a registered trademark of Beemer Precision Inc. USA

We are also able to offer bespoke Oilite sintered bearings and structural powdered metal components - click here for more information.

Oilite bearings are the most popular self-lubricating bearings in the UK, but they are also in high demand in Europe. Bowman International offers the widest choice of Oilite bearings anywhere in Europe with standard stock ranges available in metric and imperial. We stock a vast range of European sizes to ensure our customers always have the benefit of fast delivery, regardless of whereabouts in Europe they are located.

Standard Oilite bearings are impregnated with highly refined mineral oil to ISO VG (SAE 30) having a high viscosity index and containing anti-oxidant, anti-rust and defoamant additives.

A wide range of lubricants are available to meet specific requirements within a temperature range of -60°C to 200°C, lubricant additives are also available to impart anti-wear properties in marginal lubrication conditions. Special additives are also available for use with various shaft material and finishes. We are also able to offer special oil to suit customer-specific requirements.

Oilite bearings can be stored for considerable periods without deterioration or loss of oil if kept in a metal or other non-absorbent container, at room temperature. Proximity to heat could cause oil loss by sweating, in which case recoiling is necessary before fitting. Soak in oil if storage conditions are in doubt. We are able to offer Oilite bearings in sealed plastic bags or boxes.

All spherical bearings can be supplied in various grades of sintered bronze and iron, with lubricants to suit different applications. Spherical bearings can be supplied with one or two collars. Various bore tolerances and non-standard lengths can be supplied.

Oilite bearings are manufactured in three standard materials. Standard Oilite oil retaining tin bronze is the generally specified material. It gives a good balance between strength, wear resistance, conformability and durability in operation. Ideal in a wide variety of applications where self-lubricating properties are required over a long period of time.

Super Oilite® is an iron copper material suited to high static loads and slow oscillatory motion.

Iron Oilite® are 100% iron oil-retaining bearings that provide an ideal solution in high-stress low revolution applications.

Please see the Oilite® materials page for further technical details.

In the event that your requirements cannot be met by stock items, our bespoke service enables us to produce both bronze and iron Oilite bearings and customer-specific structural parts that are specifically designed to meet individual requirements. We take a consultative approach to each customer’s needs and will never try and fob you off with a bearing that is not 100% suitable and cost-effective for your project.