We are delighted to officially launch to market a split roller bearing with substantially higher radial and axial load capacities.

Ideal for higher load applications across all heavy-side sectors, our new Advanced Split Roller Bearing offers up to 75% higher radial load capacity and up to a 1000% increase in axial load capacity in both directions.  Our Technical Director, Ian Breeze, had this to say on the significance of our latest innovation:

Our Technical Director, Ian Breeze, had this to say on the significance of our latest innovation:

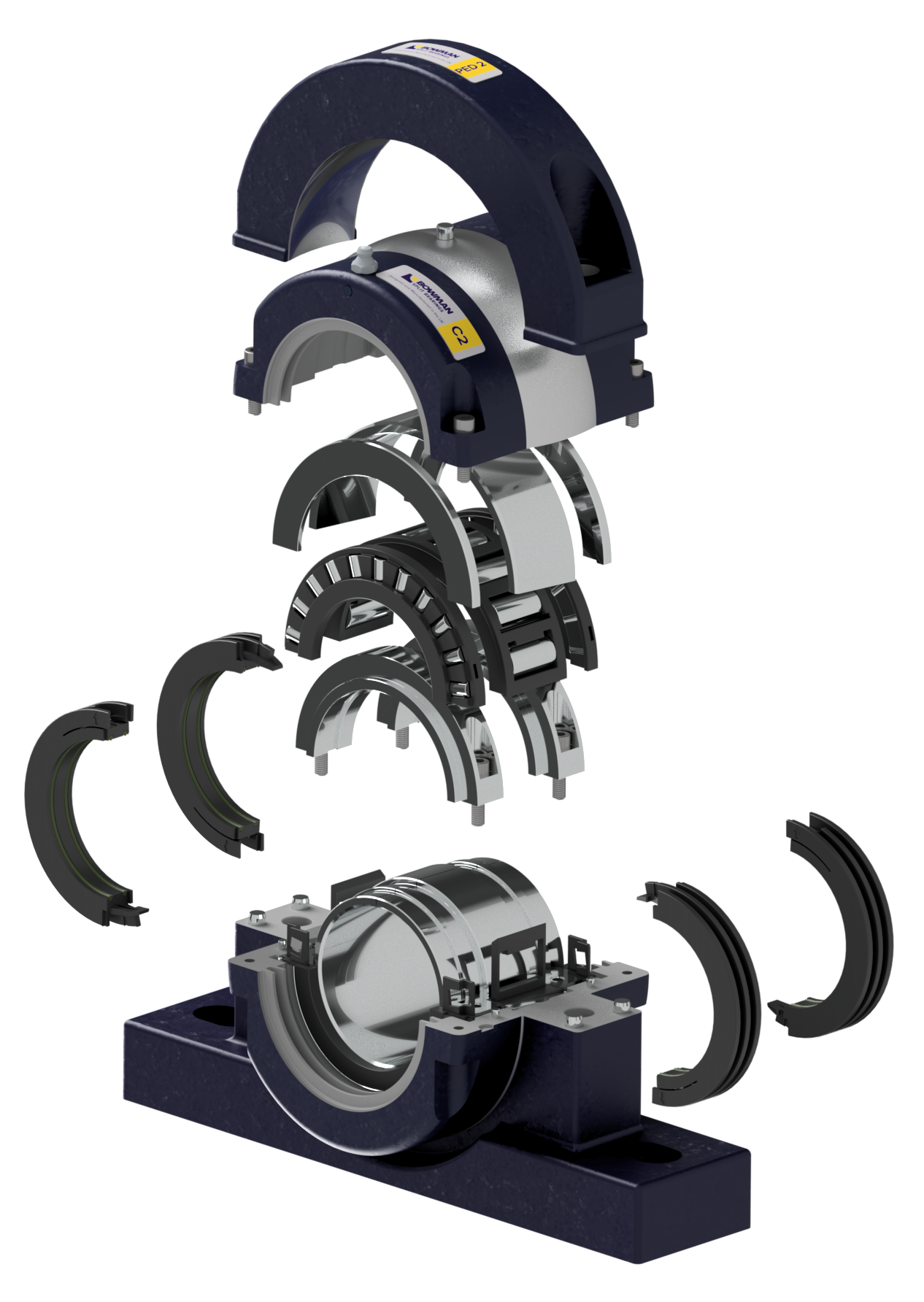

“For the first time, plant builders and maintenance engineers can specify a split roller bearing that does not rely on race lips alone to accommodate axial force in high-load applications. The new Bowman Advanced Split Roller Bearing comprises two independent 3D-printed axial bearings designed to accommodate greater loads, improving system performance with less maintenance and reducing unplanned machine failure.

“In fact, compared to other market-leading split bearings, the Bowman Advanced Split Roller Bearing increases bearing L10 life by up to 500 per cent.”

When creating this bearing, we believed we could surpass performance expectations in every way, so we integrated a patented triple labyrinth extended seal which not only offers a tighter seal than other split bearings but also reduces the need for costly removal, machining or replacement of worn shafts. Instead, engineers can simply fit an extended seal onto an undamaged part of the shaft, without compromising performance and without the need for the extended downtime.

Thanks to its high thrust capacity and increased radial load capacity, this bearing can be specified to replace solid spherical roller bearings in rotating machinery. Delivering up to ten times faster-bearing change times than previously possible for these applications. “When space is limited, engineers often need to disconnect the coupling and move other equipment, such as motors, gearboxes or pumps, out of the way before they can slide solid bearings off the shaft for replacement or maintenance,” explains Ian.

“Split roller bearings can be assembled radially around the shaft, eliminating these additional logistical challenges and making maintenance and replacement a lot faster and more cost-effective. To further enhance time and cost savings, the Bowman Advanced Split Roller Bearing uses the rollers to lock the two cage halves together, eradicating the use of small and easy to lose clips and other locking components.”

Alongside the significant increase in radial and axial load capacity, this new bearing design offers a range of additional installation and performance benefits, such as larger diameter screw sizes to accommodate increased capabilities for the clamp rings, cartridges and pedestals and roller pockets with cavities to hold the grease against the rollers.low%20res.jpg)

As part of the Advanced Split Roller Bearing portfolio, Bowman offers a range of dimensionally interchangeable retrofit products that fit directly into the existing bearing housings – even if it is from a competing bearing brand, to quickly and cost-effectively improve radial and axial load capacities. There is a choice of additional IoT specific functionalities available and bespoke adaptations can be accommodated within fast lead times.

Ian concludes: “Bowman is a proud innovator of bearing solutions that solve real industry issues. We are the first manufacturer to create a split roller bearing capable of increasing the lifespan and performance of high-axial systems and thanks to the production benefits of 3D printing, we have been able to deliver this product to market at a price point up to 20 per cent lower than other leading split bearings.”

For more information on Bowman’s new Advanced Split Roller Bearings, visit our website